1. Yini isilinda esishiselwe?Umphongolo ushiselwe ngqo kuma-caps wokugcina futhi amachweba ashiselwe emgqonyeni.Indlala yangaphambili yenduku ngokuvamile iboshiwe noma ihlanganiswe emgqonyeni wesilinda, okuvumela ukuhlangana kwenduku ye-piston kanye nezigxivizo zenduku ukuthi zikhishwe ukuze zisetshenziswe.Amasilinda we-hydraulic ashiselwe anezinzuzo eziningi ngaphezu kwamasilinda enduku yokubopha.Nakuba amasilinda enduku yokubopha angaba ishibhile ukuwakhiqiza, ngokuvamile abhekwa njengezinto “ezingekho eshalofini” futhi anezinketho ezilinganiselwe ngokwemibandela yokwenza ngokwezifiso.Futhi aziqinile kakhulu kunamasilinda ashiselwe.Amasilinda omzimba ashiselwe angenziwa ngokwezifiso ezisetshenziswa ezithile.Amasilinda ashiselwe nawo anamaphakeji ophawu aphakeme, angasiza ekwandiseni ubude besikhathi sokuphila kwesilinda futhi angasiza lapho isilinda sizosetshenziswa ezindaweni ezibandakanya ukungcola kanye nesimo sezulu.Ngobuhle, amasilinda omzimba ashiselwe anamaphrofayili aphansi kunamasilinda enduku yokubopha futhi angathuthukisa ukubukeka kwempahla asetshenziswa kuyo.Njengoba mincane kunezilinganisi ze-tie rod, amasilinda ashiselwe u-hydraulic asebenza kahle ezinhlelweni lapho isikhala siyisici.

2. Indlela yokulawula izinga lokushisela ngesikhathi sokukhiqiza ngobuningi?

Izinsiza zokushisela;Lungiselela isampula yokushisela ngokuqinile ngokwezidingo zenqubo enqunywe kusengaphambili: Ukushisa, ukushisela, ukulondolozwa kokushisa, nokulungiselela isampula yokushisela.Nokwenza ikhadi lenqubo yokushisela ukunikeza isisekelo sokuqaliswa kokushisela;Izinto zokushisela, i-welding wire kanye negesi yokushisela yizinto ezifanayo, ukusebenza okuzinzile, ukuhlanzeka kwegesi ephezulu, kanye nezilinganiso ezinembile;Umuntu oshisela, udinga ukuba nesitifiketi sokushisela;Ukuhlolwa kokushisela, okufana nokuhlola amandla obuhlalu be-weld nokuhlolwa kwe-ultrasonic ukuhlola ikhwalithi yokushisela.

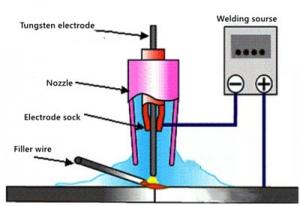

3. I-gas shielded welding ingahlukaniswa ibe i-inert gas shielded welding (i-TIG welding), i-gas shielded welding (welding ye-MAG) .Ngokusobala, i-argon isetshenziswa kakhulu ngenxa yentengo eshibhile, ngakho-ke i-inert gas shielded metal arc welding yaziwa nangokuthi i-argon arc welding.I-Tungsten inert gas welding iyinqubo yokushisela lapho kusetshenziswa i-tungsten noma i-tungsten alloy njengempahla ye-electrode, futhi i-arc ekhiqizwa phakathi kwe-electrode kanye nesisekelo sempahla isetshenziselwa ukuncibilikisa isisekelo nokugcwalisa ucingo ngaphansi kokuvikelwa kwegesi ye-inert. .

I-TIG, eyaziwa nangokuthi i-Gas Arc Welding (GTAW), iyindlela yokwenza i-Arc phakathi kwe-Tungsten electrode nesisekelo sensimbi ngaphansi kokuvikelwa kwegesi engasebenzi ukuze isisekelo sensimbi nensimbi yokushisela kuncibilike bese sishiselwa.Ihlanganisa i-DC TIG welding kanye ne-AC TIG welding.

I-DC TIG yokushisela ithatha umthombo wamandla wokushisela we-DC arc njengomthombo wamandla wokushisela, onamandla amabi ngokwedlulele kanye nezinto eziyisisekelo ezinhle.Isetshenziswa kakhulu ukushisela insimbi engagqwali, i-titanium, ithusi ne-alloy yethusi.Umthombo wamandla wokushisela we-AC TIG welding usuka ku-AC arc, futhi i-anode ne-cathode yezinto eziyisisekelo zishintshile.I-EP polarity electrode overheating ingasusa isendlalelo se-base oxide sendawo, ikakhulukazi esetshenziselwa i-aluminium, i-magnesium, nokunye ukushisela ingxubevange.

Lapho i-TIG (GTAW) i-welding operation, i-welder ingaba isibhamu sokushisela esandleni esisodwa kanye nocingo lwe-welding esandleni, olufanele ukusebenza okuncane kanye nokulungiswa kwe-welding manual.I-TIG ingakwazi ukushiselwa cishe zonke izinsimbi zezimboni, inikeza ukuma okuhle kokushisela, i-slag encane kanye nothuli kungasetshenziswa kabanzi epuleti lensimbi elincane neliwugqinsi.

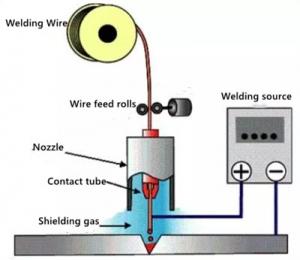

I-MAG (Metal Active Gas) I-Welding isebenzisa i-CO₂ noma ingxube ye-argon ne-CO₂ noma i-oxygen (i-Active Gas).Ukushisela igesi ye-CO₂ kwesinye isikhathi kubizwa ngokuthi yi-CO₂ arc welding.Imishini yokushisela i-MIG ne-MAG iyafana ngoba ikwazi ukuphakelwa ngaphandle kwethoshi yi-automatic wire feeder futhi ifanele ukushiselwa okuzenzakalelayo, ingasaphathwa eyokushisela ngesandla.Umehluko omkhulu phakathi kwabo usegesini evikelayo, eyokuqala ngokuvamile ivikelwe yigesi ye-argon ehlanzekile, elungele ukushisela izinsimbi ezingenayo ayoni;Ukushisela kwe-MAG ikakhulukazi kusebenzisa igesi ye-CO₂, noma i-argon exutshwe igesi ye-CO₂ esebenzayo, okuyi-Ar+2%O₂ noma i-Ar+5%CO₂, elungele ukushisela insimbi enamandla aphezulu kanye nensimbi ephezulu ye-alloy.Ukuze kuthuthukiswe ukusebenza kwenqubo ye-CO₂welding, i-CO₂+Ar noma i-CO₂+Ar+O₂ igesi exubile noma intambo ene-flux-cored ingasetshenziswa.I-MAG welding ibonakala ngesivinini sayo sokushisela, ukusebenza kahle kokuqaliswa kwe-arc ephezulu, ichibi elijulile, ukusebenza kahle kwe-deposition, ukubukeka okuhle, ukusebenza okulula, kulungele ukushiselwa kwe-high-speed pulse MIG (GMAW).

I-Fast izinikele ku-R&D kanye nokukhiqizwa kweamasilinda angama-hydraulickanye nezinhlelo ezisebenza ngamanzi, zisiza amakhasimende futhi zinikeze abasebenzi impilo engcono.Kuze kube manje, sisize izinkulungwane zamaklayenti kuwo wonke umhlaba ohlinzeka ngobungcweti bokwenza isilinda esisebenza ngehydraulic kanye nokwakhiwa kwesistimu ngezinzuzo ezincintisanayo.

Isikhathi sokuthumela: Sep-16-2022